In recent years, fibre optic termination methods have become more advanced with several methods now common practice in the industry. Choosing the right termination method for your cable will depend on a range of factors including the installation environment, connector performance, tools, and your budget. In this blog, we will outline the three most common methods of fibre optic termination to help you choose the suitable termination method that will reduce cost and maximise efficiency on your project.

Pigtail Splicing

This first fibre optic termination method we’re going to explore is pigtail splicing. This is a commonly used fibre splicing technique. A pigtail is a piece of cable with one or multiple factory-polished connectors at one at end bare fibre on the other.

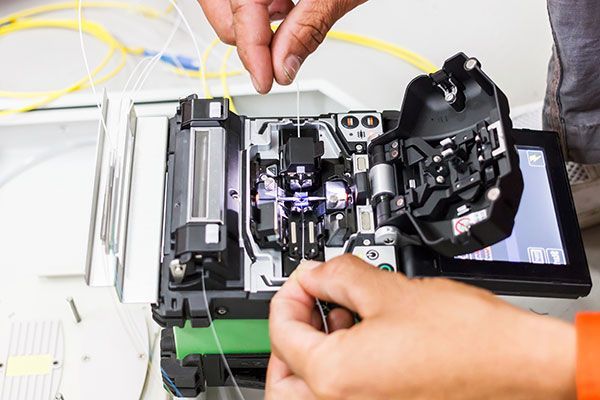

To complete this termination method, the installer will first need to secure and route the fibre-optic and pigtail cable in a splice tray. Then the bare end of the cable is spliced to field fibre. Once this is complete, the splice is routed into the splice tray which is then installed into the hardware.

To perform this type of fibre optic termination method, the installer needs a high level of experience. This method will also require the use of a fusion splicer and cleaver.

No-Epoxy/ No-Polish (NENP) Connector

Another way to successfully terminate fibre is to use a no-epoxy/no-polish (NENP) connector. This method is the fastest and simplest way for a newer installer to complete. This termination method is faster because the connector’s face is polished in the factory and the field fibre is mechanically spliced to a factory-cleaved fibre stub. The NENP connector termination method only takes about 2-3 minutes to complete and is relatively quick to install. You will require a NENP toolkit.

Firstly, the field fibre must be prepared by stripping the protective coating down to bare glass. Then the field fibre is inserted into the connector until placed against the factory-stubbed fibre. It is then locked into place mechanically using the tools that hold the connector.

Epoxy-and-Polish

The final method of fibre-optic termination we’re going to explore is using an epoxy-and-polish (EP) connector. This semi-complex termination method can take up to 5 minutes and will require an EP tool kit.

To perform termination through an EP connector, epoxy is inserted into the connector ferrule. The field fibre is then stripped and cleaned. If the connector is anaerobic, the bare fibre is painted with an activator and inserted into the connector. If it is a heat-cure connector, fibre is inserted into the connector and placed in an oven for the epoxy to cure. Once cured, the fibre stub above the ferrule is removed. The final step is to polish the end face of the connector using polishing films.

Things to Consider

Whatever termination method you choose, an important factor to consider is the process being followed in accordance with industry standards. To successfully terminate a fibre optic cable, you should employ a certified and experienced installer. This is what the team at CableNet Industries can provide.

Contact CableNet Industries

CableNet Industries provides a range of cable and fibre optic services including fanout kits, fibre splicing, cable hauling, cable testing and commissioning, cable blowing and fibre and cable ploughing. We perform our services Australia-wide form our offices in Sunshine West, Victoria and Yatala, Queensland. Reach us anywhere across Brisbane, Sydney, Canberra, Melbourne, Adelaide, Perth, Darwin and beyond. Contact now.